It decreases the steam consumption. It is proven that 1 mm of scale thickness on heat transfer surfaces will increase the fuel consumption of about 2.5% at boiler.

It decreases the power consumption because almost all pumps are continuously running even when plant running at low capacity.

Plant will be running at higher capacity for longer period of time and also assist in easy removal of scale and sludge deposits making cleaning more easier.

No of Plant shut downs and/or break downs will be reduced, increasing life span of the plant.

Due to reduced cleaning frequency and downtime, overall maintenance cost decreases and help shorten the payback period.

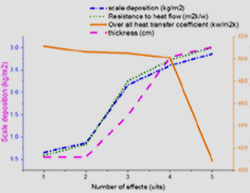

Most of the Multiple Effect Evaporator plants of different industries; are operated below their rated capacity in-spite of correct steam pressure and vacuum is provided.

The reason is organic and inorganic deposition on heat transfer surfaces. It leads to very high economic penalties like:

For efficient operation of any MEE; the basic requirement is to maintain scale free heat transfer surfaces of evaporator to run the plant at maximum capacity, at the same time, to keep thermal and electrical energy cost at minimum.

The scaling on heat transfer surfaces is due to hardness, silica, iron, sulfates and other impurities coming in to the feed.

Our anti scalant will keep scale forming constituents in dispersed complex form during the process of concentrating and preventing them from adhering to heat transfer surfaces. Therefore the plant will be running at maximum capacity for longer period without cleaning, at the same time, whatever little scale will be formed on heat transfer surface will be very less and can be cleaned easily so that cleaning time will be reduced drastically than usually required. Ultimately downtime, cost of cleaning and cost of maintenance will be reduced.

As per P.C.R.A. it is established that 1 mm thickness of scale in the boiler will increase the fuel consumption of the boiler to about 6 %.

Our experience of boilers includes from Lancashire to fluidized bed boilers in different types of industries, we suggest our proven multi functions boiler additives for internal boiler water treatment which helps in following ways by keeping the heat transfer surfaces free from scale and corrosion and allows maximum heat transfer from fuel to water.

Only one product SCALONTM-901 at very low dosage includes pH booster, antifoaming agent, sludge dispersant, scale inhibitor, corrosion inhibitor and oxygen scavenger which is not possible by any other conventional water treatments programs.

The advanced tri functional synthetic liquid formulation designed to control scale, corrosion and organic fouling in open recirculating cooling water system.

SCALONTM products at very low dosage efficiently works as dispersant, scale inhibitor, corrosion inhibitor and biocide which is not possible by any other conventional water treatment programs.

The cooling water treatment includes Antiscalant, Corrosion Inhibitor, Dispersant and Biocide for control of Algae, fungus Bacteria etc.